Dante Villa

Storia

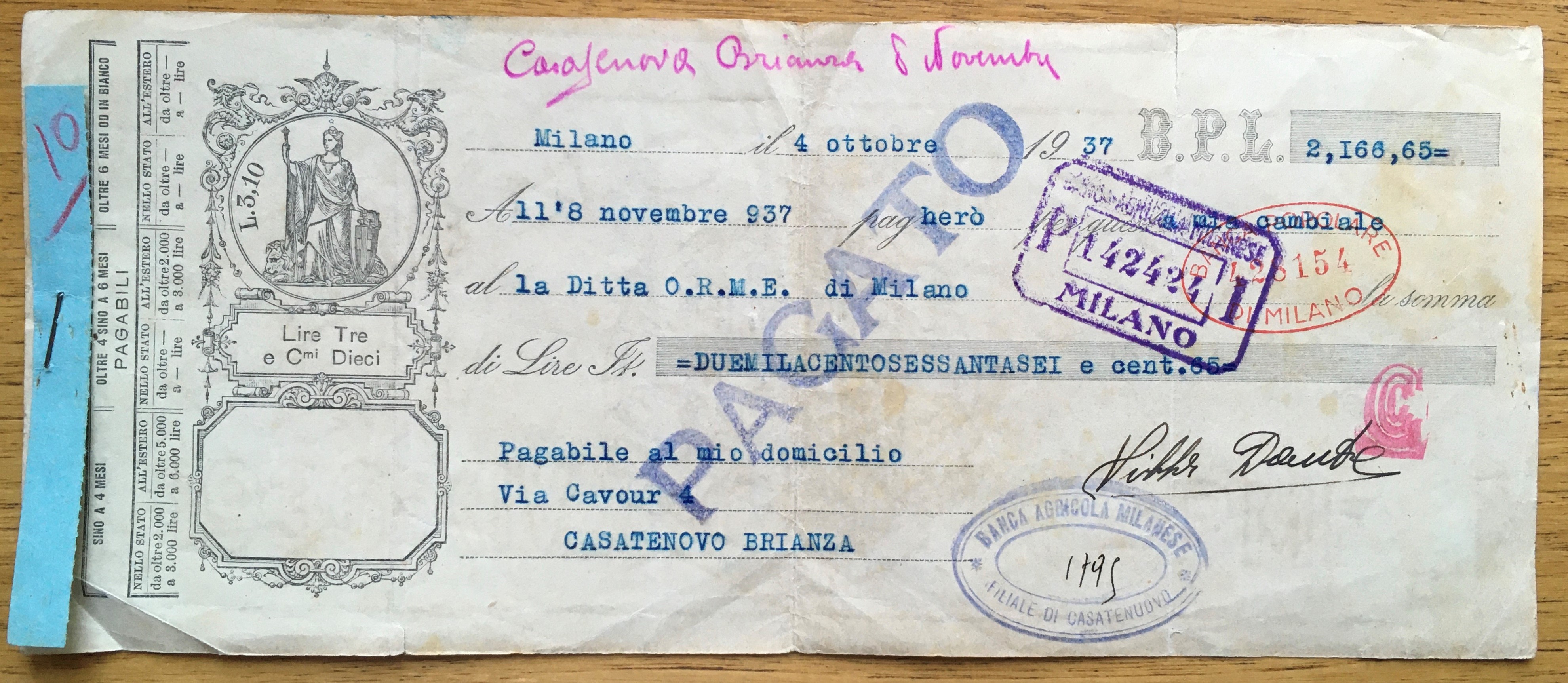

Dal 1937 impegnati nella torneria automatica

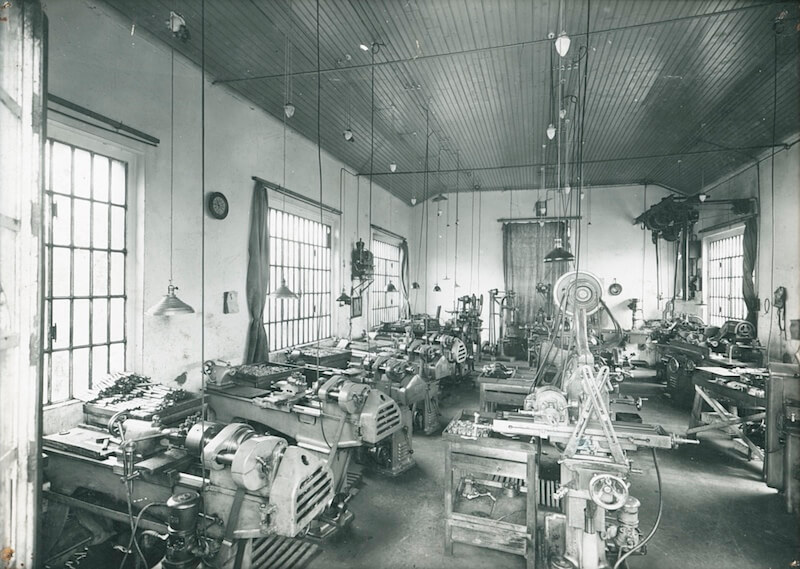

La nostra azienda opera dal 1937 nel settore industriale come torneria automatica impegnata nella realizzazione di minuteria metallica di precisione a disegno del cliente. Disponendo di attrezzature tecnologicamente avanzate, siamo in grado di soddisfare le più svariate esigenze dell’industria meccanica, in particolare automobilistica, dei componenti oleodinamici e pneumatici, oltre che della produzione di una vasta gamma di cuscinetti a sfera su disegno del cliente.

Il reparto operativo è dotato di torni automatici plurimandrino, meccanici e asserviti con CNC, che permettono di eseguire particolari speciali, dotati di diametri ed esagoni variabili da 3 a 70 millimetri, i quali possono essere ripresi e finiti grazie all’utilizzo di rettificatrici per esterni e per interni, fresatrici e impianti di assemblaggio. Un reparto di lavaggio e finitura superficiale assolve le nuove richieste, secondo le più complesse specifiche di pulizia granulometrica, con lo scopo di consegnare al cliente prodotti finiti e corrispondenti alle richieste, le più esigenti.

Contattaci per informazioni o per un preventivo